Situs Blog

Blog terbaru

Blog Kategori

Hubungi kami

- Jika Anda memiliki pertanyaan, silahkan hubungi kami, Semua pertanyaan akan dijawab

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Tambahkan : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Hot produk

blog

Coin Cell Case

A coin cell case is a compact, hermetically sealed container designed to house small, circular batteries commonly used in portable electronic devices. These cases are widely employed in applications such as watches, medical devices, RFID tags, and IoT sensors due to their lightweight, spaceefficient design and reliable performance.

In this article, we will explore the structure, materials, manufacturing process, advantages, challenges, and applications of coin cell cases.

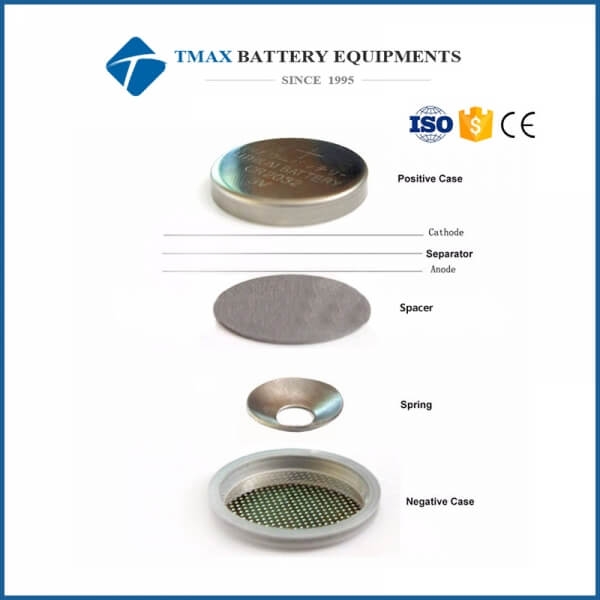

●Structure of a Coin Cell Case

A typical coin cell case consists of two main components:

1. Positive Terminal (Cathode Can)

The cathode can serves as the positive electrode and houses the battery's cathode material.

It is usually made of stainless steel or nickelplated steel for durability and conductivity.

2. Negative Terminal (Anode Cap)

The anode cap serves as the negative electrode and includes a gasket or seal to ensure hermeticity.

It is often made of the same materials as the cathode can but may include additional coatings for insulation.

3. Seal/Gasket

A critical component that prevents electrolyte leakage and external contamination.

Commonly made of polypropylene, polyethylene, or other polymerbased materials.

4. Electrolyte and Separator

Inside the case, the electrolyte facilitates ion movement, while the separator prevents short circuits between the electrodes.

●Materials Used in Coin Cell Cases

1. Metallic Components

Stainless steel or nickelplated steel for the cathode can and anode cap due to their corrosion resistance, strength, and electrical conductivity.

2. Sealing Materials

Polymers like polypropylene or polyethylene for the gasket/seal to ensure longterm hermeticity.

3. Coatings

Insulating coatings on the anode cap to prevent electrical shorts.

●Manufacturing Process of Coin Cell Cases

The production of coin cell cases involves several precise steps:

1. Stamping and Forming

Metal sheets are stamped and formed into the desired shape for the cathode can and anode cap.

2. Cleaning and PreTreatment

Components are cleaned and treated to remove impurities and ensure proper adhesion of coatings.

3. Assembly

The cathode can is filled with electrolyte and separator, and the anode cap is placed on top.

4. Sealing

The case is hermetically sealed using techniques such as crimping, laser welding, or ultrasonic welding to ensure a leakproof enclosure.

5. Quality Control

Each assembled coin cell case undergoes rigorous testing for hermeticity, electrical performance, and mechanical integrity.

●Advantages of Coin Cell Cases

1. Compact Size

Ideal for spaceconstrained applications, such as wearable devices and smart cards.

2. High Reliability

Hermetic sealing ensures longterm performance and resistance to environmental factors like moisture and dust.

3. CostEffective

Mass production techniques make coin cell cases economical for largescale applications.

4. Versatility

Suitable for various battery chemistries, including lithiumion, lithium manganese dioxide, and silver oxide.

5. Ease of Integration

Simple design allows for easy incorporation into electronic devices.

●Challenges in Coin Cell Case Design and Manufacturing

1. Leakage Prevention

Ensuring a perfect seal is critical to prevent electrolyte leakage, which can damage the device or reduce battery life.

2. Material Compatibility

Selecting materials that are compatible with the battery chemistry while maintaining mechanical strength and conductivity.

3. Miniaturization

As devices become smaller, designing ultrathin coin cell cases without compromising performance poses significant engineering challenges.

4. Environmental Impact

Disposal of coin cell cases and their contents can contribute to electronic waste, necessitating sustainable solutions.

●Applications of Coin Cell Cases

Coin cell cases are used in a wide range of industries and applications:

1. Consumer Electronics

Watches, calculators, key fobs, and remote controls.

2. Medical Devices

Pacemakers, hearing aids, and implantable sensors.

3. IoT and Wearables

Smartwatches, fitness trackers, and wireless sensors.

4. Security Systems

RFID tags, access control devices, and alarm systems.

5. Industrial Applications

Backup power for memory storage, realtime clocks, and data loggers.

●Innovations in Coin Cell Case Technology

To address challenges and enhance performance, manufacturers are developing advanced coin cell case solutions:

1. Thinner Designs

Ultrathin cases for use in nextgeneration wearable devices and flexible electronics.

2. Improved Sealing Techniques

Advanced welding and bonding methods to ensure superior hermeticity.

3. Sustainable Materials

Use of recyclable or biodegradable materials to reduce environmental impact.

4. Customizable Solutions

Tailored designs for specific applications, such as hightemperature or highvibration environments.

5. Integration with Smart Features

Incorporating sensors or communication modules into coin cell cases for enhanced functionality.

●The Future of Coin Cell Cases

As demand for compact, reliable power sources grows, so too will advancements in coin cell case technology. Key trends shaping the future include:

1. Increased Miniaturization

Development of even smaller and thinner cases for emerging applications like microelectronics and nanotechnology.

2. Focus on Sustainability

Ecofriendly designs and materials to minimize environmental impact.

3. Integration with Emerging Technologies

Combining coin cell cases with AI, IoT, and cloud computing for smarter diagnostics and monitoring.

4. Global Standards Compliance

Ensuring compatibility with evolving international regulations for battery packaging.

5. Expansion into New Markets

Adapting coin cell cases for emerging fields like aerospace, marine, and quantum computing.

●Conclusion

Coin cell cases are a vital component of modern battery technology, enabling the efficient and reliable operation of countless electronic devices. Their compact size, high reliability, and versatility make them indispensable in today's connected world.

February 3,2026.

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

A coin cell case is a compact, hermetically sealed container designed to house small, circular batteries commonly used in portable electronic devices. These cases are widely employed in applications such as watches, medical devices, RFID tags, and IoT sensors due to their lightweight, spaceefficient design and reliable performance.

In this article, we will explore the structure, materials, manufacturing process, advantages, challenges, and applications of coin cell cases.

●Structure of a Coin Cell Case

A typical coin cell case consists of two main components:

1. Positive Terminal (Cathode Can)

The cathode can serves as the positive electrode and houses the battery's cathode material.

It is usually made of stainless steel or nickelplated steel for durability and conductivity.

2. Negative Terminal (Anode Cap)

The anode cap serves as the negative electrode and includes a gasket or seal to ensure hermeticity.

It is often made of the same materials as the cathode can but may include additional coatings for insulation.

3. Seal/Gasket

A critical component that prevents electrolyte leakage and external contamination.

Commonly made of polypropylene, polyethylene, or other polymerbased materials.

4. Electrolyte and Separator

Inside the case, the electrolyte facilitates ion movement, while the separator prevents short circuits between the electrodes.

●Materials Used in Coin Cell Cases

1. Metallic Components

Stainless steel or nickelplated steel for the cathode can and anode cap due to their corrosion resistance, strength, and electrical conductivity.

2. Sealing Materials

Polymers like polypropylene or polyethylene for the gasket/seal to ensure longterm hermeticity.

3. Coatings

Insulating coatings on the anode cap to prevent electrical shorts.

●Manufacturing Process of Coin Cell Cases

The production of coin cell cases involves several precise steps:

1. Stamping and Forming

Metal sheets are stamped and formed into the desired shape for the cathode can and anode cap.

2. Cleaning and PreTreatment

Components are cleaned and treated to remove impurities and ensure proper adhesion of coatings.

3. Assembly

The cathode can is filled with electrolyte and separator, and the anode cap is placed on top.

4. Sealing

The case is hermetically sealed using techniques such as crimping, laser welding, or ultrasonic welding to ensure a leakproof enclosure.

5. Quality Control

Each assembled coin cell case undergoes rigorous testing for hermeticity, electrical performance, and mechanical integrity.

●Advantages of Coin Cell Cases

1. Compact Size

Ideal for spaceconstrained applications, such as wearable devices and smart cards.

2. High Reliability

Hermetic sealing ensures longterm performance and resistance to environmental factors like moisture and dust.

3. CostEffective

Mass production techniques make coin cell cases economical for largescale applications.

4. Versatility

Suitable for various battery chemistries, including lithiumion, lithium manganese dioxide, and silver oxide.

5. Ease of Integration

Simple design allows for easy incorporation into electronic devices.

●Challenges in Coin Cell Case Design and Manufacturing

1. Leakage Prevention

Ensuring a perfect seal is critical to prevent electrolyte leakage, which can damage the device or reduce battery life.

2. Material Compatibility

Selecting materials that are compatible with the battery chemistry while maintaining mechanical strength and conductivity.

3. Miniaturization

As devices become smaller, designing ultrathin coin cell cases without compromising performance poses significant engineering challenges.

4. Environmental Impact

Disposal of coin cell cases and their contents can contribute to electronic waste, necessitating sustainable solutions.

●Applications of Coin Cell Cases

Coin cell cases are used in a wide range of industries and applications:

1. Consumer Electronics

Watches, calculators, key fobs, and remote controls.

2. Medical Devices

Pacemakers, hearing aids, and implantable sensors.

3. IoT and Wearables

Smartwatches, fitness trackers, and wireless sensors.

4. Security Systems

RFID tags, access control devices, and alarm systems.

5. Industrial Applications

Backup power for memory storage, realtime clocks, and data loggers.

●Innovations in Coin Cell Case Technology

To address challenges and enhance performance, manufacturers are developing advanced coin cell case solutions:

1. Thinner Designs

Ultrathin cases for use in nextgeneration wearable devices and flexible electronics.

2. Improved Sealing Techniques

Advanced welding and bonding methods to ensure superior hermeticity.

3. Sustainable Materials

Use of recyclable or biodegradable materials to reduce environmental impact.

4. Customizable Solutions

Tailored designs for specific applications, such as hightemperature or highvibration environments.

5. Integration with Smart Features

Incorporating sensors or communication modules into coin cell cases for enhanced functionality.

●The Future of Coin Cell Cases

As demand for compact, reliable power sources grows, so too will advancements in coin cell case technology. Key trends shaping the future include:

1. Increased Miniaturization

Development of even smaller and thinner cases for emerging applications like microelectronics and nanotechnology.

2. Focus on Sustainability

Ecofriendly designs and materials to minimize environmental impact.

3. Integration with Emerging Technologies

Combining coin cell cases with AI, IoT, and cloud computing for smarter diagnostics and monitoring.

4. Global Standards Compliance

Ensuring compatibility with evolving international regulations for battery packaging.

5. Expansion into New Markets

Adapting coin cell cases for emerging fields like aerospace, marine, and quantum computing.

●Conclusion

Coin cell cases are a vital component of modern battery technology, enabling the efficient and reliable operation of countless electronic devices. Their compact size, high reliability, and versatility make them indispensable in today's connected world.

What excites you most about the advancements in coin cell case technology? Share your thoughts below! Together, let’s explore how these innovative solutions can shape the future of portable energy storage and device design.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com