Situs Blog

Blog terbaru

Blog Kategori

Hubungi kami

- Jika Anda memiliki pertanyaan, silahkan hubungi kami, Semua pertanyaan akan dijawab

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Tambahkan : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Hot produk

Mesin Laboratorium Baterai Litium

EV Car battery production plant

June 5,2023.

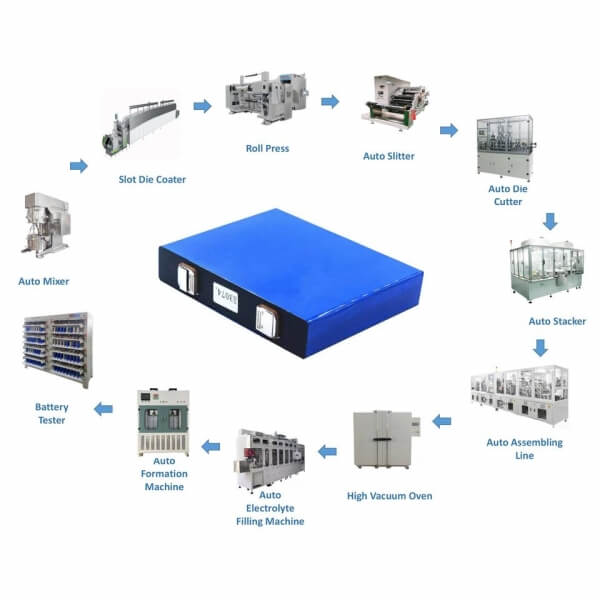

EV car battery production plant. It involves several key aspects and knowledge areas:

Battery Chemistry: Understanding the chemistry of EV batteries, such as lithium-ion, lithium iron phosphate (LiFePO4), or solid-state batteries. This includes knowledge of electrode materials, electrolytes, and cell construction.

Production Equipment: Familiarity with the machinery and equipment required for battery production, including electrode coating machines, cell assembly lines, formation equipment, battery testing systems, and packaging machinery.

Quality Control: Implementing rigorous quality control processes to ensure that batteries meet industry standards and customer requirements. This involves testing battery performance, safety features, and cycle life.

Safety Considerations: Implementing safety measures to handle hazardous materials, such as electrolytes and flammable substances. This includes proper ventilation, fire prevention systems, and training for handling and storage procedures.

Automation and Robotics: Incorporating automation and robotics technologies to increase production efficiency, precision, and reduce manual labor. This includes automated assembly lines, robotic handling systems, and advanced control systems.

Supply Chain Management: Coordinating the supply chain to ensure a steady and reliable flow of raw materials, components, and equipment for battery production. This includes managing suppliers, logistics, and inventory.

Environmental Sustainability: Incorporating environmentally friendly practices in the production process, such as recycling and proper disposal of hazardous materials. This includes adhering to local regulations and industry standards for environmental protection.

Research and Development: Keeping up with the latest advancements in battery technology, exploring new materials, and improving production processes to enhance battery performance, energy density, and safety.

Regulatory Compliance: Adhering to relevant regulations and certifications, such as ISO standards and safety certifications, to ensure compliance with industry and government requirements.

Continuous Improvement: Implementing continuous improvement initiatives to optimize production efficiency, reduce costs, and enhance product quality.

Battery Chemistry: Understanding the chemistry of EV batteries, such as lithium-ion, lithium iron phosphate (LiFePO4), or solid-state batteries. This includes knowledge of electrode materials, electrolytes, and cell construction.

Production Equipment: Familiarity with the machinery and equipment required for battery production, including electrode coating machines, cell assembly lines, formation equipment, battery testing systems, and packaging machinery.

Quality Control: Implementing rigorous quality control processes to ensure that batteries meet industry standards and customer requirements. This involves testing battery performance, safety features, and cycle life.

Safety Considerations: Implementing safety measures to handle hazardous materials, such as electrolytes and flammable substances. This includes proper ventilation, fire prevention systems, and training for handling and storage procedures.

Automation and Robotics: Incorporating automation and robotics technologies to increase production efficiency, precision, and reduce manual labor. This includes automated assembly lines, robotic handling systems, and advanced control systems.

Supply Chain Management: Coordinating the supply chain to ensure a steady and reliable flow of raw materials, components, and equipment for battery production. This includes managing suppliers, logistics, and inventory.

Environmental Sustainability: Incorporating environmentally friendly practices in the production process, such as recycling and proper disposal of hazardous materials. This includes adhering to local regulations and industry standards for environmental protection.

Research and Development: Keeping up with the latest advancements in battery technology, exploring new materials, and improving production processes to enhance battery performance, energy density, and safety.

Regulatory Compliance: Adhering to relevant regulations and certifications, such as ISO standards and safety certifications, to ensure compliance with industry and government requirements.

Continuous Improvement: Implementing continuous improvement initiatives to optimize production efficiency, reduce costs, and enhance product quality.

A comprehensive understanding of these areas is crucial for the successful establishment and operation of an EV car battery production plant. It requires a combination of technical expertise, knowledge of industry trends, and adherence to safety and environmental regulations to produce high-quality batteries that meet the growing demand for electric vehicles.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com