Situs Blog

Hubungi kami

- Jika Anda memiliki pertanyaan, silahkan hubungi kami, Semua pertanyaan akan dijawab

- Email : David@tmaxcn.com

- Email : Davidtmaxcn@gmail.com

- Tambahkan : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

Hot produk

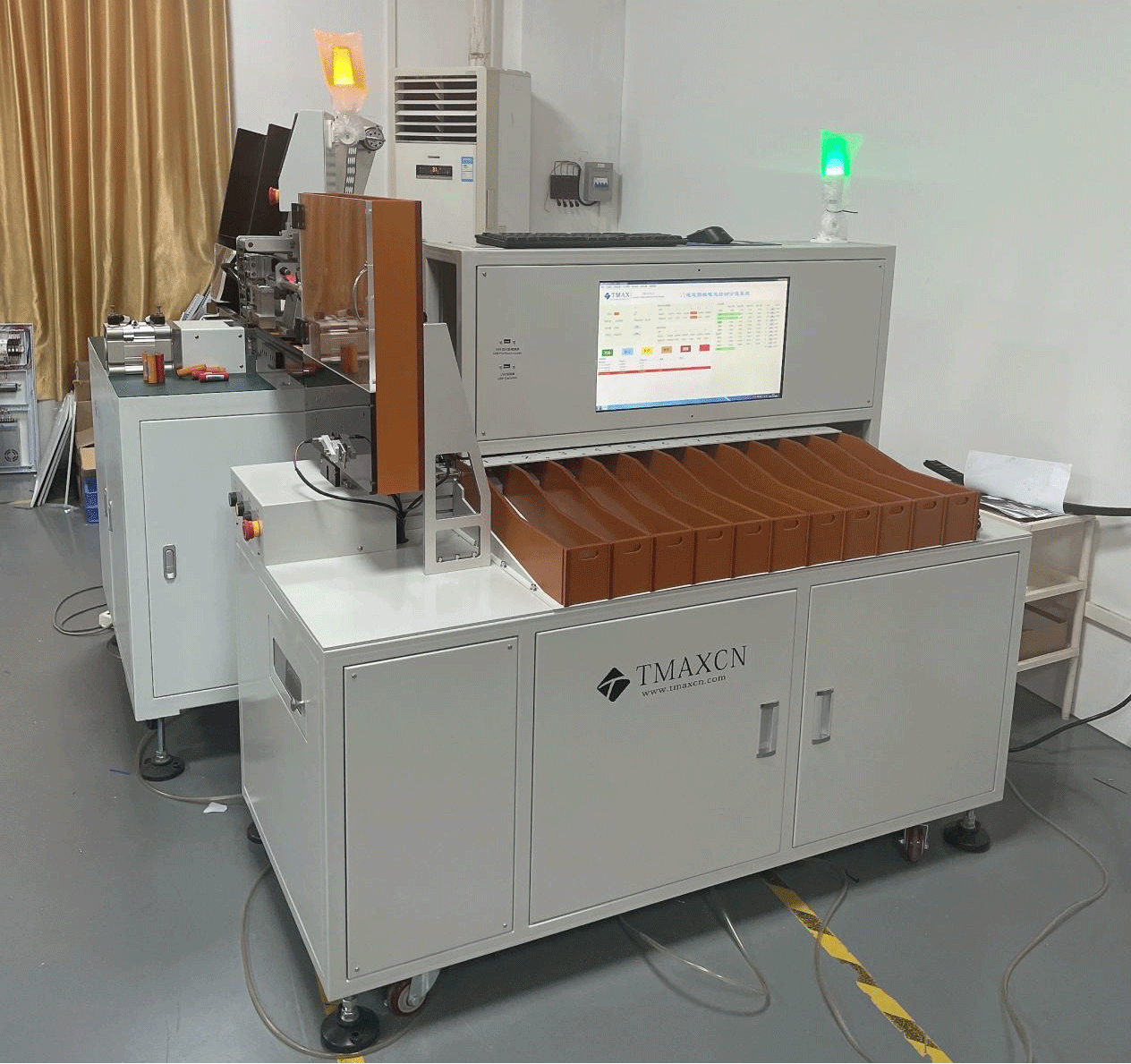

Battery Pack Assembly machine is a highly automated system designed to assemble battery packs from individual battery cells. The machine typically includes several stations, each of which is responsible for a specific step in the assembly process.

The first station is the Lithium cell sorting machine, where individual battery cells are sorted and grouped according to their capacity, voltage, and other parameters. This is a critical step in ensuring that the final battery pack has consistent performance and meets the required specifications.

Next, the cells are sent to the cell tab welding station, where tabs made of nickel or other conductive material are welded to the cell terminals. This is another critical step in the assembly process, as it ensures that each cell is connected to the rest of the pack and can contribute to its overall performance.

The cells with welded tabs are then transferred to the insulation station, where they are covered with insulating material, such as polyethylene foam, to prevent electrical contact between the cells. This is important for safety reasons, as well as for maintaining the performance and longevity of the battery pack.

After insulation, the cells are stacked and placed in a pack enclosure, which can be made of plastic, metal, or other materials. The enclosure is then sealed using a heat sealing process, adhesive, or other means, depending on the specific design of the pack.

Once the pack is complete, it undergoes rigorous testing to ensure that it meets the required quality and performance standards. This testing typically includes electrical performance testing, environmental durability testing, and safety testing.

Battery Pack Assembly line are essential for efficient and scalable production of high-quality battery packs. These machines are used in a wide range of industries, including electric vehicles, portable electronics, and grid energy storage systems, to produce battery packs that are reliable, safe, and cost-effective.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com